Customer Overview

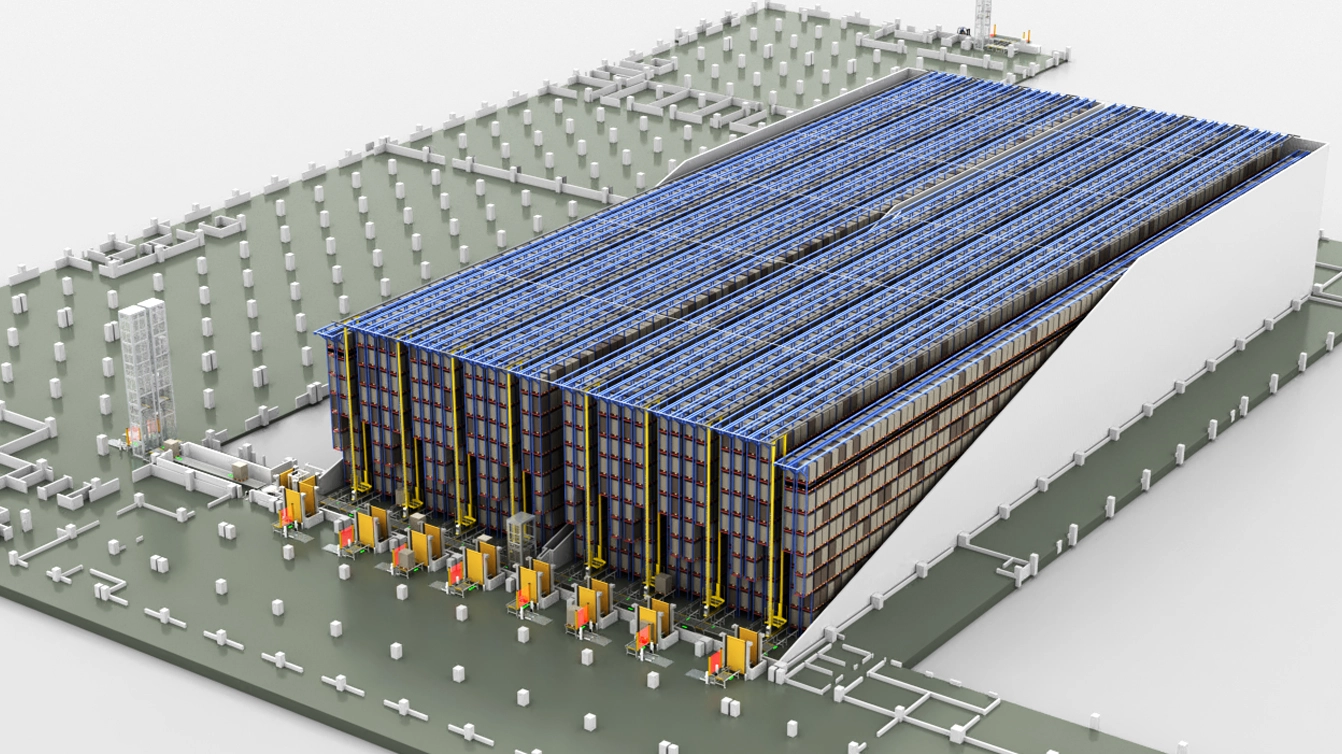

The overall automated three-dimensional cold storage meets the storage and warehousing capacity of various quick-frozen products with a total of 290 pallets per hour; the three-dimensional warehouse and the production workshop are connected by a conveyor line, and the materials on each floor of the workshop are transported to the mezzanine on the first floor by a hoist for warehousing operations.

A total of 26,688 cargo positions

Handling process: automatic palletizing line/manual palletizing → silo hoist.

Products: 8 pallet stackers

System configuration: WMS warehouse management system, intelligent and automated hardware-software process

Solved the problems of low automation of material storage and insufficient space utilization.

Cooperative docking: conveyor lines and elevators need to be coordinated and docked, and the labor efficiency is low.

Cost investment: three shifts, repeated ineffective operations, and costs have risen year by year.

Flexible logistics: the site space is compact and does not support secondary transformation of the site environment.

Operation efficiency: there is no warehouse information management on site, and the efficiency of picking up and finding goods is slow.

Increase storage capacity by 4.5 times

Increase efficiency by 10%

Increase timeliness by 8%

Precise docking

All-round security