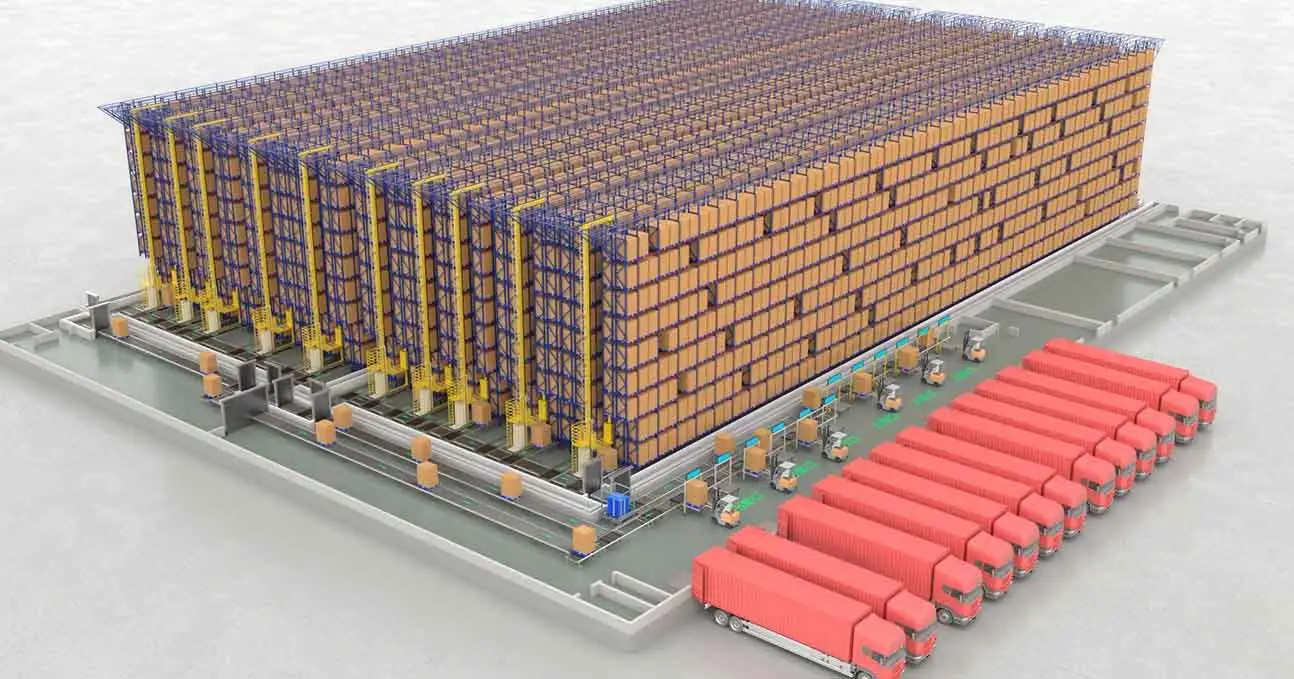

Optimize automation process and on-site system management. The system supports the docking of multiple logistics equipment with high efficiency, high flexibility and high scalability to achieve full logistics automation.

Based on big data, it realizes interconnection with other logistics equipment and warehousing equipment, and moves from single products to systematic applications.

Integrated intelligent manufacturing logistics solutions help customers significantly reduce costs, improve efficiency, and provide continuous value.

Opening up relevant upstream and downstream links such as production, warehousing, and logistics can improve efficiency by more than 20%, and realize information management and visual management of Kanban.

Save labor costs, improve driving safety, improve work efficiency, and reduce operating expenses such as maintenance and repair costs.

Adopt safety configurations that are superior to peers to improve equipment safety and stability;

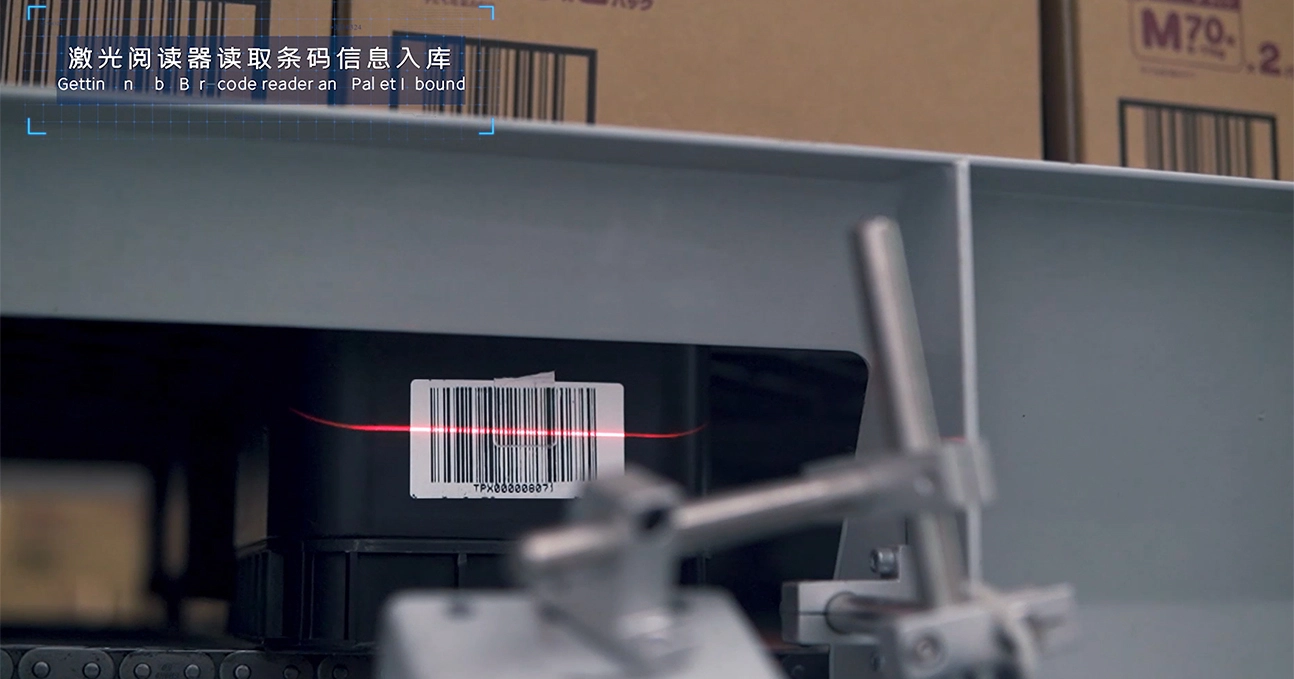

Adopt laser barcode positioning and absolute value positioning methods to make positioning more accurate;

Electrical components use internationally renowned brands, and the cold chain industry uses low-temperature environment design.

Inbound solutions comprehensively cover raw materials, semi-finished products, inventory replenishment and return processing, accurately and efficiently advancing each process and simplifying each step. It not only ensures that inventory is accurately in place and optimizes storage layout, but also greatly reduces the labor cost and time consumption of warehouse inbound operations, making inbound management smarter and more efficient.

Intelligent

Multi-dimensional inventory, customized reports

All-round visual management

Efficient

Intelligent waves and inbound strategies

Powerful operating rules and strategies support balanced inventory distribution

Safety

Visual pallet inspection to ensure shelf safety

Box damage detection to ensure product safety

Cost reduction

Release repeated labor and reduce error rate

Reduce labor costs and increase safety and reliability

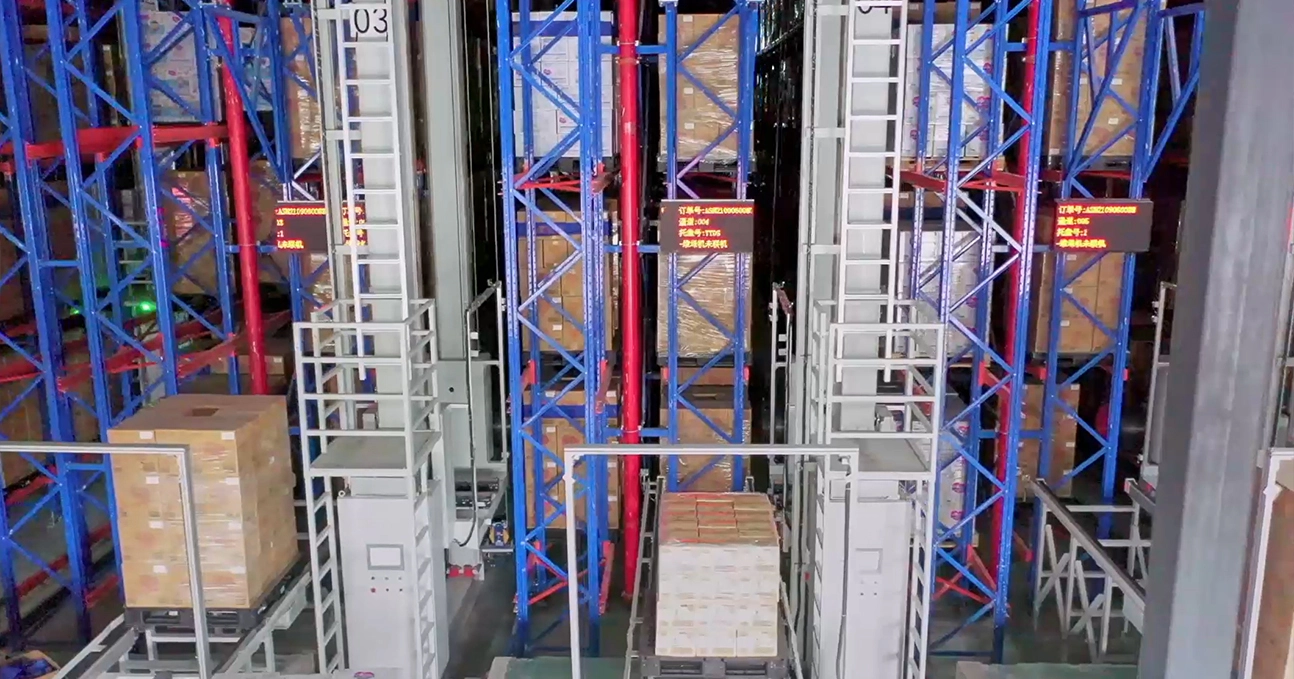

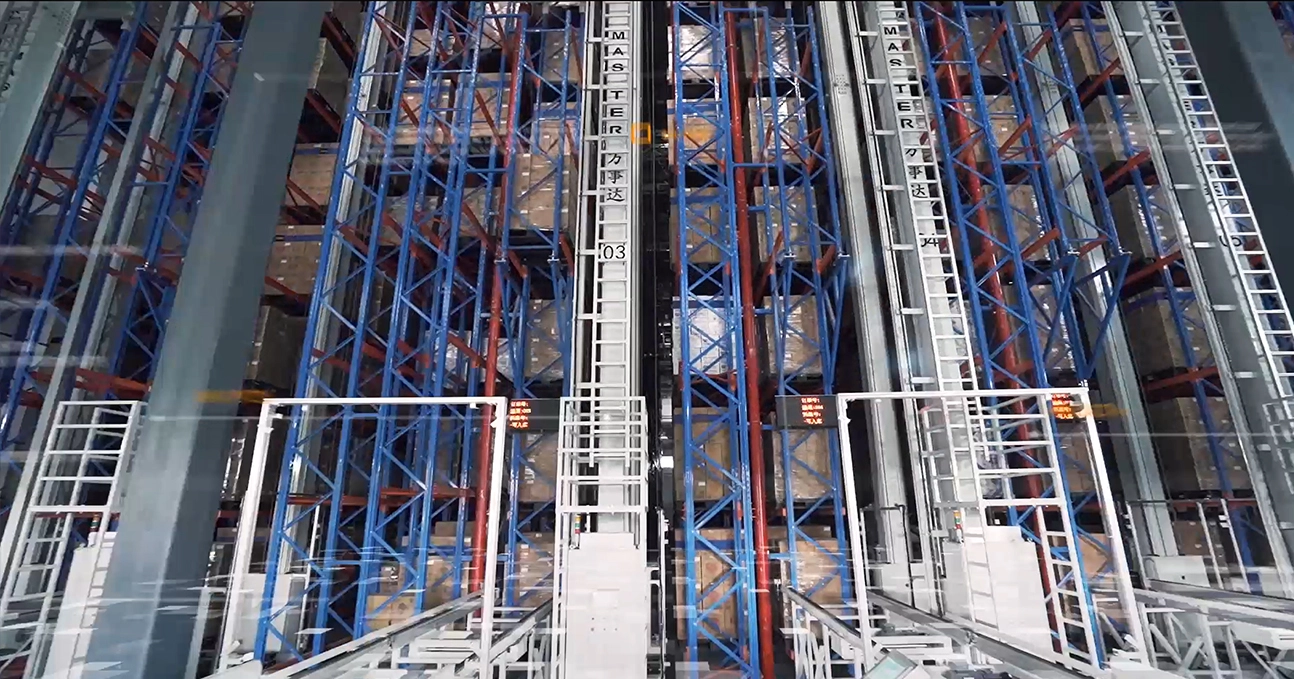

Whether it is the storage and retrieval of goods in the form of large pallets or small boxes, Master's high-quality racking systems can meet various complex storage needs. With the help of technical means, we can significantly improve storage space utilization, effectively reduce storage costs, and create smarter and more economical storage solutions for you.

reliable

Extremely high equipment maturity

Efficient and stable operation

Efficient

Improve labor productivity

Improve inventory accuracy

Safety

Visual detection of foreign objects on track to protect human and machine safety

Visual inspection of warehouse locations to ensure stacking safety

save

Optimize space utilization

Reduce operating costs

With the help of Master technology algorithm, the sorting efficiency has greatly increased, laying a solid foundation for the enterprise's warehouse transformation and promoting its development in the direction of unmanned, automated and intelligent. Deeply integrated into the picking process, it achieves a qualitative leap in speed, accuracy and efficiency. By minimizing the work intensity of pickers and optimizing walking paths, the efficiency and accuracy of product sorting in various business scenarios are significantly improved, and the enterprise's warehousing operation model is comprehensively reshaped and upgraded.

Flexible

Short deployment cycle; easy to expand and maintain

Dynamic scene adaptation

High work efficiency

Fine intelligent scheduling algorithm; optimal path allocation

Intelligent congestion avoidance algorithm

Operation visible

Warehouse map layout is visible; robot status and scheduling are visible

Visualization of the completion of transportation tasks

Fast return on investment

Replace manual picking and save manpower

Greatly improve picking efficiency

Provide corresponding technical support for conventional pallets, cartons, material boxes, and special goods of various shapes. Self-developed software technology enables material transportation scenarios and responds to various complex tasks more intelligently. It greatly reduces the company's operating costs, improves work efficiency, and optimizes management processes unprecedentedly

Quick deployment

Flexible layout

Flexible and scalable

General scheduling

Cluster scheduling

Intelligent scheduling algorithm

Automation improvement

Visual management

Wide industry application

Various scenarios

Improve accuracy and safety

Flexibility for peak and seasonal products

In the outbound process, Master provides a series of innovative and forward-looking intelligent solutions to safeguard the efficient and accurate operation of smart warehousing, so that it can always run steadily on a high-efficiency track and complete each outbound task accurately and without error.

Rapid deployment

Flexible layout

Flexible and scalable

General scheduling

Cluster scheduling

Intelligent scheduling algorithm

Automation improvement

Visual management

Wide industry application

Various scenarios

Improve accuracy and safety

Flexibility for peak and seasonal products