Customer overview

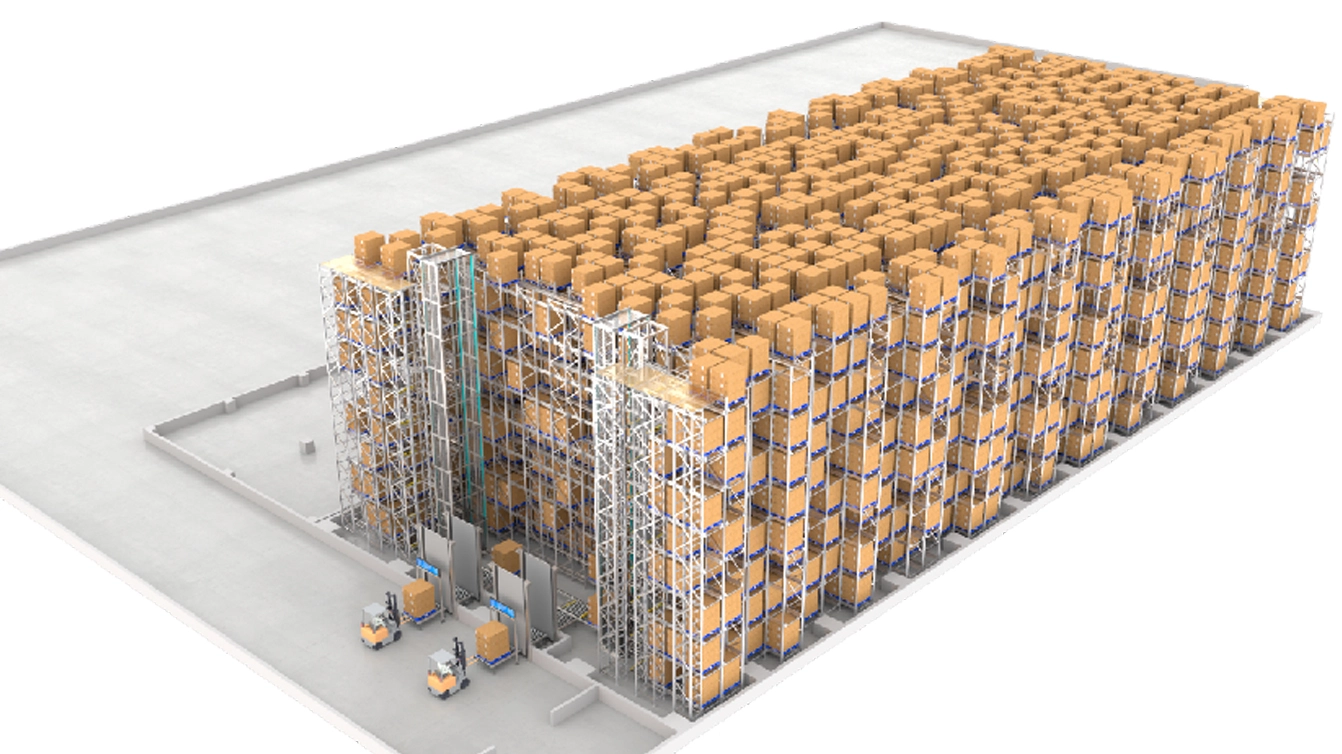

This is the first intelligent three-dimensional cold storage in Northwest China. It is an urban and rural cold chain logistics facility project.

The annual throughput is about 20,000 tons. Responsible for the storage and in-and-out management of meat finished products.

The project covers an area of about 2,134 square meters

5,000-ton intelligent three-dimensional cold storage project

The total number of cargo positions in the warehouse is 7,182 pallets

Selected products: 6 pallet four-way vehicles and 2 pallet elevators

System configuration: WMS warehouse management system, improve the customer's warehouse management level, intelligent + information

Solved the problems of low automation of material storage and insufficient space utilization.

Cooperative docking: Conveyor lines and elevators need to be coordinated and docked, and labor efficiency is low.

Cost investment: three shifts, repeated ineffective operations, and costs are rising year by year.

Flexible logistics: The site space is compact and does not support secondary transformation of the site environment.

Operation efficiency: There is no warehouse information management on site, and the efficiency of picking up and finding goods is slow.

Increase storage capacity by 4.5 times

Increase efficiency by 10%

Increase timeliness by 8%

Reduce 8 workers

All-round safety guarantee