Customer overview

The company's products are exported to the United States, Japan, South Korea, Hong Kong, Vietnam and other places, and are widely used in various general equipment such as mobile phones and computers, and enjoy a high reputation in the industry.

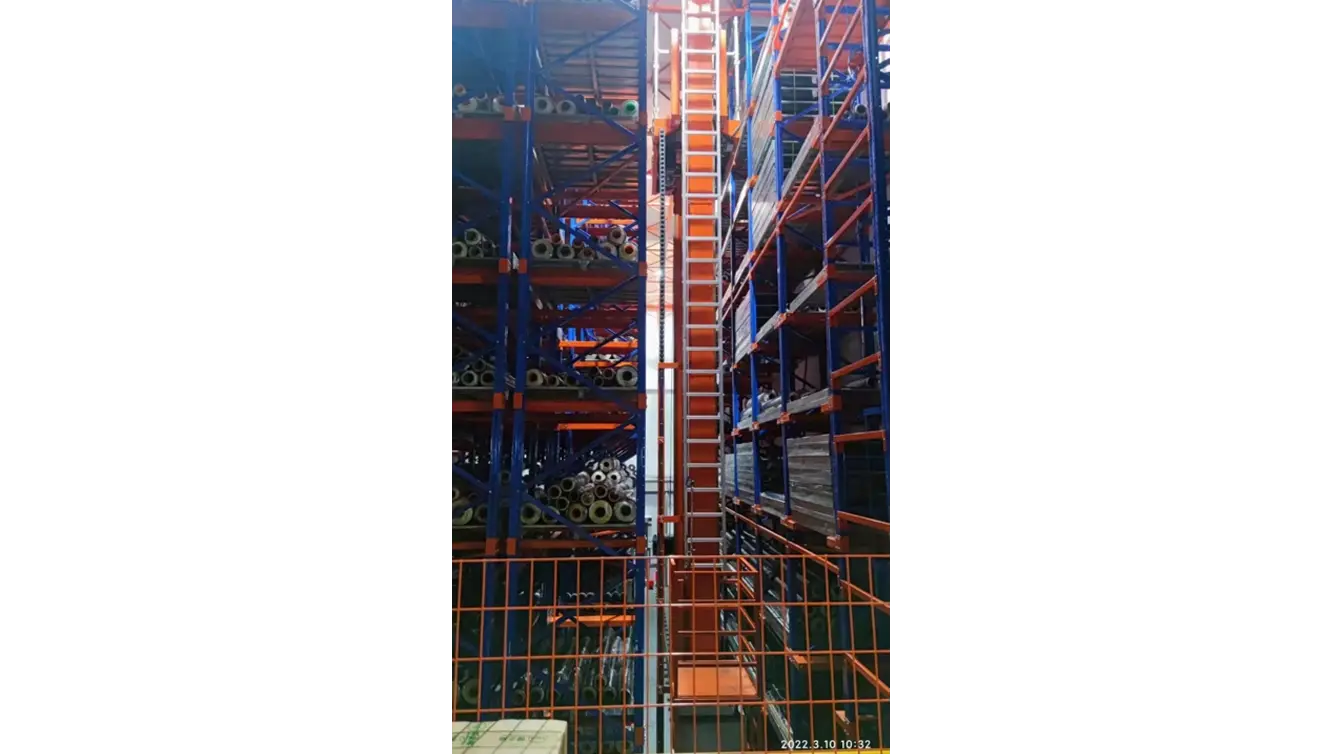

Old warehouse renovation project: dismantling of original equipment in the old warehouse and arrangement of new equipment.

Transportation process: automatic stacking line/manual stacking → silo elevator.

Selected products: 4 pallet four-way vehicles and 3 pallet elevators

System configuration: WMS warehouse management system, intelligent and automated hardware-software full process

Corridor transportation: The logistics flow lines of warehouses and production workshops are optimal, effectively improving the efficiency of material handling

Solved the problems of low automation of material storage and insufficient space utilization.

Cooperative docking: requires coordinated docking of conveyor lines and elevators, and low labor efficiency.

Cost investment: three shifts, repeated ineffective operations, and rising costs year after year.

Shape monitoring: Manual palletizing is highly random, and it is time-consuming and laborious to return unqualified shapes.

Flexible logistics: The site space is compact and does not support secondary transformation of the site environment.

Operation efficiency: There is no warehouse information management on site, and the efficiency of picking and finding goods is slow.

Increase storage capacity by 4.5 times

Increase efficiency by 10%

Increase timeliness by 8%

Reduce 6 workers

Accurate docking

All-round safety guarantee